CSR Environment Projects

Project on Green Cooling –Development of Cold Chains for rural India

Background

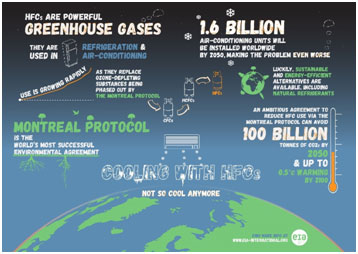

In the 28th meeting of the Parties to the Montreal Protocol, negotiators from 197 nations have signed an historic agreement to amend the Montreal Protocol in Kigali, a capital city of a tiny African country, Rwanda on 15th October 2016.

- As per the agreement, these countries are expected to reduce the manufacture and use of Hydrofluorocarbons (HFCs) by roughly 80-85% from their respective baselines, till 2045.

- This phase down is expected to arrest the global average temperature rise up to 0.5o C by 2100.

- Kigali agreement is an amendment to Montreal Protocol.

- The Montreal Protocol is a most effective international environmental treaty to phase out the Ozone Depleting Substances (ODSs) from the atmosphere.

- It came into force in 1989.

- It has 197 member parties to the protocol and become a first international treaty with complete ratification.

- It has undergone several amendments and Kigali amendment is the eighth amendment to this protocol.

- It has successfully curbed the 98% production of chlorofluorocarbons and other ODSs and significantly contributed to the repair of the ozone hole.

The Montreal Protocol on Substances that Deplete the Ozone Layer was designed to reduce the production and consumption of ozone depleting substances in order to reduce their abundance in the atmosphere, and thereby protect the earth’s fragile ozone Layer. The protocol was agreed on September 16th in 1987 and entered into force on January 1st in 1989.

Kigali Agreement: Important Points

- It is a legally binding agreement between the signatory parties with non-compliance measures.

- It will come into effect from 1st January 2019 provided it is ratified by at least 20 member parties by then.

- It has shown a considerable flexibility in approach while setting phase-down targets for different economies accommodating their developmental aspirations, different socio-economic compulsions, and scientific & technological capabilities.

It has divided the signatory parties into three groups-- The first group consists of rich and developed economies like USA, UK and EU countries who will start to phase down HFCs by 2019 and reduce it to 15% of 2012 levels by 2036.

- The second group consists of emerging economies like China, Brazil as well as some African countries who will start phase down by 2024 and reduce it to 20% of 2021 levels by 2045.

- The third group consists of developing economies and some of the hottest climatic countries like India, Pakistan, Iran, Saudi Arabia who will start phasing down HFCs by 2028 and reduce it to 15% of 2024-2026 levels till 2047.

- It also has a provision for a multilateral fund for developing countries for adaptation and mitigation.

- The Technology and Energy Assessment Panel (TEAP) will take a periodic review of the alternative technologies and products for their energy efficiency and safety standards.

Why is Kigali Agreement significant?

- It strengthens the Paris Agreement which sets an ambitious target of restricting the rise in global temperature below 2O Celsius, as compared to pre-industrial level.

- Unlike Paris agreement, it gives clear, concrete and mandatory targets with fixed timelines to the signatory parties to achieve their targets.

- It would prevent the emission of HFCs equivalent to 70 billion tons of CO2.

Kigali Amendment and India

- India played a very flexible and cooperative role in the whole negotiating process.

- It has agreed on a lenient schedule as it consumes only 3% of HFCs as compared to the other nations like the USA (37%) and China (25%).

- It would be tough for Indian to adhere to this agreement along with Paris Pact especially when it has embarked on an ambitious ”Make in India” Program to increase its industrial production.

- It should also take into consideration the hot climatic conditions and growing demand for air conditioners, refrigerators, and cars with growing middle-class incomes while implementing the program.

- Still, as a responsible nation with a global perspective, the Indian government has voluntarily passed the order to stop the production of HFC-23 which is a byproduct of commonly used refrigerant. This will reduce the emission by 100 million tons equivalent of Carbon dioxide in next 15 years.

Implications of Kigali Agreement on India

Indian industries using HFCs like Air-Conditioning industry, Automobiles, and refrigeration industry have some serious implications on financial and technical fronts:

- Financial implications – Industries have to either invest in R & D to find out the substitutes for HFCs or they have to buy patented substances and technologies from other MNCs. Consequently, the cost of production will increase which may ultimately shrink the buyer base for their products.

- Technological implications – Some of the developed nations have already started using substitutes of HFCs in their products and have a sound technological knowledge about their use. Without technology transfer or research, it would be difficult for domestic industries to compete with them in global as well as domestic market.

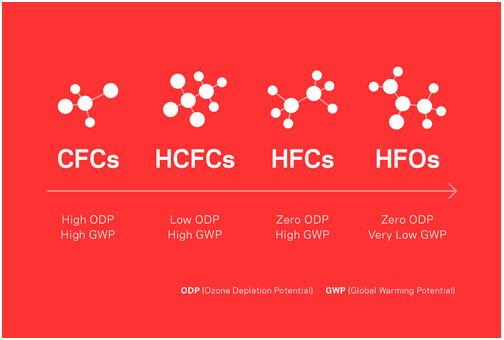

What next, after HFCs?

The answer is HFO refrigerants. HFO stands for hydrofluoro olefin. HFC refrigerants are composed of hydrogen, fluorine and carbon atoms connected by single bonds between the atoms. HFO refrigerants are composed of hydrogen, fluorine and carbon atoms, but contain at least one double bond between the carbon atoms.

HFO-1234yf has physical properties similar to HFC-134a. Therefore, HFO-1234yf has the potential to be used in current HFC-134a systems with minimal system modifications.

India`s HPMP phase out Management Plan stage II is launched to ensure timely and sustainable phase out of HCFC.

Project Concept: Cold Chain development for Small and Medium Farmers of India

Background

Jwala India project is designed to support small and medium farmers to find resources to develop innovative products and processes that minimize ozone and climate impacts, while remaining safe ,efficient and affordable and profitable.

- Post-harvest losses oftentimes accounts for up to 50% of the total harvest due to inadequate storage and transport. Only 10% of the world’s perishable foodstuffs are contemporarily being refrigerated post-harvest. By improving access to refrigeration in India, spoilage of up to 40% of perishable foods could be prevented.

- India suffers losses of up to INR 440 bn in fruit and vegetables each year due to the absence of effective technologies to keep produce cool. Less than 4% of India’s fresh produce is transported by cold chain.

- India has around 6,300 cold storage facilities, with a capacity of 30.11 million tonnes and there is a need for US$ 15 billion investment over the next 5 years with capacity increase of 40% to avoid wastage.

- The infrastructure Gap in Cold chains is presented in table below:

| Type Of Infrastructure | Infrastructure Requirement (A) | Infrastructure Created (B) | All India Gap (A-B) |

|---|---|---|---|

| Pack-house | 70.080 nos. | 249 nos. | 69,831 nos. |

| Cold Storage (BUlk) | 341,64,411 MT | 318,23,700 MT | 32,76,962 MT |

| Cold Storage (Hub) | 9,36,251 MT | ||

| Cold Storage (Hub) | 9,36,251 MT | ||

| Reefer Vehicles | 61,826 nos. | 9,000 nos. | 52,826 nos. |

| Ripening Chamber | 9,.131 nos. | 812 nos. | 8,319 nos. |

Proposed Activity to Build-up and improvement of climate-friendly and energy-efficient food cold chains with the expected outcome that such intervention will lead to increased food security and safety.

Target Group : Small and Medium Farmers

Location : Pan India

- Broadcast Best practice examples: transport refrigeration in South Africa, sustainable fish cold stores in Kenya, solar powered refrigerators in Swaziland, cooling cabinets running on the natural refrigerant propane in supermarkets in South Africa.

- Integrate cold chain management into the Agriculture and horticulture sector by conducting awareness and capacity programs.

- Support Small and medium farmers to update them about financial and technology and infrastructure development of cold chains.

- Develop forward and backward linkages to develop community cold chains for small and marginal farmers.

- Training and skill development of youth of the village as Servicing Staff.

Project On Bio CNG: Cost Effective solution of GHG Mitigation

Background

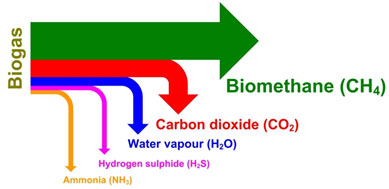

Biogas is formed when organic biodegradable feedstock such as cow dung, poultry litter, other excreta, organic municipal solid waste (MSW), biomass etc. ferments and is degraded by bacteria under anaerobic conditions. Biogas is a mixture of:

- Methane (CH4 – 50% to 70%)

- Carbon dioxide (CO2 – 30% to 45%)

- Minor impurities/contaminants comprising of gases such as hydrogen sulfide (H2S – ppm to 3%).

- Moisture (H2O)

Biogas is Renewable form of Energy. However, when any biodegradable organic matter breaks down anaerobically, it naturally produces biogas which releases methane to the atmosphere. This gas has a very high Global Warming Potential of 21 as compared to 1 for carbon dioxide and contributes significantly to climate change and pollution. If biogas is fermented, a process often referred to as biomethanation, in digester under controlled conditions, it can be utilized for various purposes such as heating and cooling, generation of power and production of biomethane, which when compressed is also referred to as bioCNG.

Biogas formed in a biomethane digester is stored in a gas holder or balloon. The biogas is thereafter purified where carbon dioxide, moisture and other minor gaseous impurities are removed. The purified biogas is fed to the compressor where it is compressed and filled into cylinders. This gas is called compressed biomethane or BioCNG.

Commercial Aspect

Typical Data a 1000 NM3/Day Capacity Biogas Purification Project are…

Capacity: 1000 NM3/Day

Dung Required: 20 Tons/Day

Water required: 15 Tons/Day

Bio-CNG Production: 400 Kg/Day

Manure Production: 6 Tons/Day

Selling Price of Bio-CNG: Rs. 40 -80/Kg

Selling price of Manure: Rs. 3/Kg

Price: Approximately

Biogas Plant: 1,10,00,000/-

Biogas Purification Plant: 25,00,000/-

Bio-CNG Compressor: 20,00,000/-

Bio-CNG Storage: 40,00,000/-

Vehicles: 20,00,000/-

Land Preparation & Other Civil Work: 20,00,000/-

Land Requirement: ~ 2 Acres Subsidy: ~ 20 Lakhs (depending on project capacity)

Payback Period: ~ 4 – 5 Years

Use of and Benefits of Bio-CNG

When Carbon dioxide and all other impurities such as H2S are removed, purified methane gas that remains is called biomethane and, if it is compressed, it is often referred to as BioCNG. It can be used to provide energy in a way that reduces net greenhouse gas emissions.

BioCNG can be utilized for many purposes such as:

- Heating replacing LPG and gaseous & liquid fuels

- Cooling replacing electricity used for refrigeration

- Cogen – Combined Heat and Power (CHP)

- Trigen – Combined Heat, Refrigeration/Cooling and Power

- Transport fuel to supplement liquid and gaseous fuel

- Biomethane can be used as feedstock for producing chemicals

Potential of Bio-CNG in India

Any significant sources of biodegradable organic matter can be used to produce BioCNG. It has been estimated that in India has the highest population of cattle in India. If cattle dung is properly collected, on a realistic basis, and used efficiently, BioCNG produced can possibly replace more than 4.0 mill. T of LPG per year. In addition, there are other very significant sources/feedstocks for production of BioCNG that need to be examined in detail such as:

Piggery waste, poultry waste etc

Biomass generated from agro-waste and other such sources straws, bagasse etc.

Industries which can become significant contributors such as Distillery (Alcohol/Ethanol), food processing industries etc

MSW, vegetable waste from Markets, whole sale mandis, kitchen waste of large corporate

Canteens, community centers, schools, temples and hospitals, Mandees and landfills, Garden waste, energy crops etc

Biogas from Sewage Treatment Plant

Project Cost: Approximately Rs 1.5 -1.75 Cr to Rs 10-12 Cr.

Scalable & Replication

The BioCNG project has its great advantage that it can be easily replicated and scalable depending on the supply of feedstock.

Power generation from BIO GAS is another best option to meet the power required. The energy from BioCNG can be easily stored and it is unlike wind, hydro & solar.

Jwala India has the capability to install Bio CNG plants on B-O-T terms and conditions in the NCR, Maharashtra, Uttar Pradesh, Gujarat, Rajasthan, Madhya Pradesh and Bihar

Project on Climate Finance & Climate Change Adaptation

Background

India and 171 other countries signed Paris Agreement at the High-level signing ceremony at UN General Assembly on April 22, 2016. India reiterated that it would reduce Emission Intensity by 35%.; Build 40% capacity for Power Generation from non-fossil fuels; Create additional carbon sink of 2.5 billion tonnes and invest in reducing our vulnerability and enhancing adaptation to Climate Change. Under the Cancun Adaptation Framework (CAF), India soon will launch its National Adaptation Plan to combat the climate change.

Innovation and CSR Fund

The CSR fund can be utilized as Climate Finance for innovative projects for Climate Change Adaptation & Mitigation

Innovative Adaptation Project Ideas

- Use of Hydro-phonics Technology for farming in the drought prone regions of India

- Introduction of new farming techniques and capacity building for sustainable farming in flood prone regions.

- Introduction of Zero tillage, value chains , storage and marketing of Agri Products etc

- Water Source Protection and Soil Conservation through Reforestation

- Sustainable Management of the rice crop for Climate Change Adaptation

- Knowledge and Tools for Sustainable Management of Water and Soils

- Soil Recovery with Organic Composting, Crop and Soil Conservation Structures

- Adapting to Climate Change through the Application of Green Forest

- Reforestation and Soil Conservation to Improve Tree Nurseries for Adaptation

- Tree Nursery Activities for Reforestation

- Land & Preservation Measures to Combat CC Pressures

Innovative Mitigation Project Ideas

- Solar water pumping for irrigation purposes

- Retrofitting energy systems to a less polluting source of energy

- Upgrading lighting and insulation in municipal facilities such as community centres, arenas, libraries or other municipal buildings

- Changing a fuel source from fossil fuels to a less polluting source of clean energy like wind, hydro and solar

- Creating an energy recovery loop to channel waste energy to heat

- Using digested solids from a wastewater treatment plant to generate gas for electricity or heat

- Capturing, processing and treating methane gas from landfill sites to produce energy

Contact for further details:

Pamposh Bhat

Trustee & Chairperson,

K-1525, PalamVihar

Gurgoan, Haryana 122017

Tel/Fax: +911244382494

Mob: +919810744555

Email:chairperson@jwalaindia.org

Alt:bhat.pamposh@gmail.com

Vinay Singh

Director, Projects &Programs

M: +91-9004542365

Email: vinay.singh@jwalaindia.org

Alt: vinaysingh2006@gmail.com